PNNL team develops carbon nanotube-silicon microspheres as high-performance Li-ion anodes

Silicon is an appealing anode material for Li-ion batteries because it can hold about 10 times the electrical charge per gram compared to graphite. However, silicon suffers from large volume change during lithiation/delithiation, leading to structure failure. Although nanostructured Si can mitigate that structure failure, nanomaterials, with their high surface area and low tap density, can be detrimental for both their electrochemical performance and practical manufacturing.

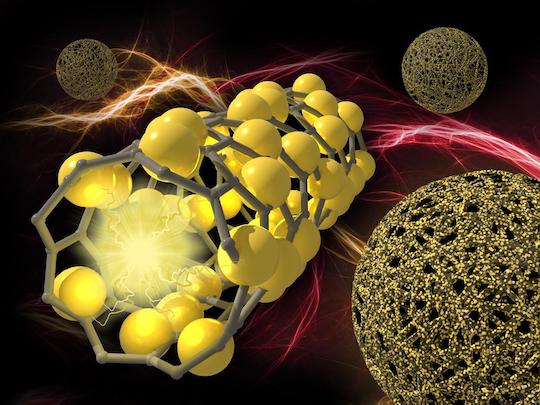

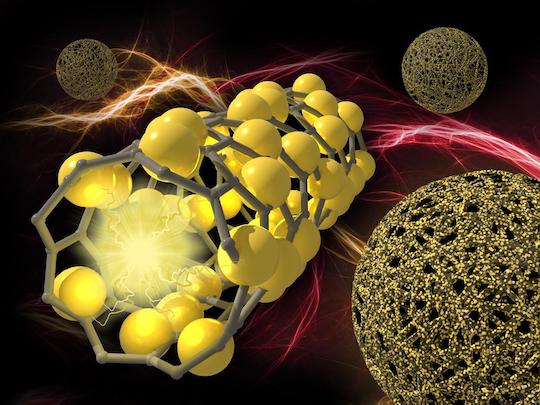

To tackle these issues, a team led by Pacific Northwest National Laboratory (PNNL) researchers Ji-Guang (Jason) Zhang and Xiaolin Li has developed a nanostructure that limits silicon’s expansion while fortifying it with carbon. The unique hierarchical porous CNT@Si@carbon (CNT@Si@C) microspheres, which feature high mechanical strength and limited particle swelling upon full lithiation, are developed with well-engineered structural parameters (small primary Si particle size, controlled porosity, and surface area, high-quality carbon coating, etc).

Here we design and synthesize hierarchical carbon-nanotube@silicon@carbon microspheres with both high porosity and extraordinary mechanical strength (>200 MPa) and a low apparent particle expansion of ~40% upon full lithiation. The composite electrodes of carbon-nanotube@silicon@carbon-graphite with a practical loading (3 mAh cm−2) deliver ~750 mAh g−1 specific capacity, <20% initial swelling at 100% state-of-charge, and ~92% capacity retention over 500 cycles.

Calendered electrodes achieve ~980 mAh cm−3 volumetric capacity density and <50% end-of-life swell after 120 cycles. Full cells with LiNi⅓Mn⅓Co⅓O2 cathodes demonstrate >92% capacity retention over 500 cycles.— Jia et al.

Calendered electrodes achieve ~980 mAh cm−3 volumetric capacity density and <50% end-of-life swell after 120 cycles. Full cells with LiNi⅓Mn⅓Co⅓O2 cathodes demonstrate >92% capacity retention over 500 cycles.— Jia et al.

Their work, which was recently published in an open-access paper in the journal Nature Communications, could inform new electrode material designs for other types of batteries and eventually help increase the energy capacity of the lithium-ion batteries in electric cars, electronic devices, and other equipment.

The researchers created their porous form of silicon by aggregating small silicon particles into microspheres about 8 micrometers in diameter—roughly the size of one red blood cell.

A solid material like stone, for example, will break if it expands too much in volume. What we created is more sponge-like, where there is space inside to absorb the expansion. — Jason Zhang

The electrode with porous silicon structure exhibits a change in thickness of less than 20 percent while accommodating twice the charge of a typical graphite anode, the study found. However, unlike previous versions of porous silicon, the microspheres also exhibited extraordinary mechanical strength, due to carbon nanotubes that make the spheres resemble balls of yarn.

The researchers created the structure in several steps, starting by coating the carbon nanotubes with silicon oxide. Next, the nanotubes were put into an emulsion of oil and water. Then they were heated to boiling.

The coated carbon nanotubes condense into spheres when the water evaporates. Then we used aluminum and higher heat to convert the silicon oxide into silicon, followed by immersion in water and acid to remove by-products. — Xiaolin Li

What emerges from the process is a powder composed of the tiny silicon particles on the surface of carbon nanotubes.

The porous silicon spheres’ strength was tested using the probe of an atomic force microscope. The authors found that one of the nanosized yarn balls “may yield slightly and lose some porosity under very high compressing force, but it will not break.”

This augurs well for commercialization, because anode materials must be able to handle high compression in rollers during manufacturing. The next step, Zhang said, is to develop more scalable and economical methods for making the silicon microspheres so that they can one day make their way into the next generation of high-performance lithium-ion batteries.

Resources Jia, H., Li, X., Song, J. et al. (2020) “Hierarchical porous silicon structures with extraordinary mechanical strength as high-performance lithium-ion battery anodes.” Nat Commun 11, 1474 doi: 10.1038/s41467-020-15217-9

Fonte: https://www.greencarcongress.com/

Ultima consultazione il 07 Maggio 2020

Recent Comments