Energy storage systems: the solution in graphene silicon?

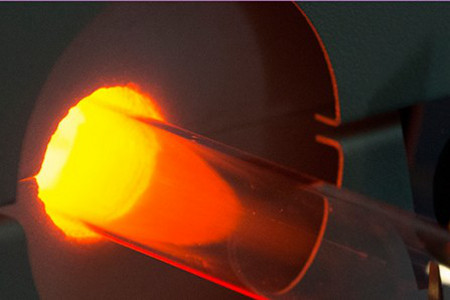

Researchers from Vanderbilt University in Nashville, Tennessee are studying renewable energy storage systems in silicon chips thanks to supercapacitors. Vanderbilt scientists created the first supercapacitor (also called supercapacitor, that is, a particular electric capacitor capable of storing huge quantities of energy compared to its small size) made of silicon. This invention opens up the possibility of integrating both the storage of electricity and all the electronics needed to manage electricity supply in a single electronic chip. If this possibility proves to be usable at acceptable costs, in addition to having cell phones with supercapacitor batteries that recharge in a few moments, photovoltaic panels with an integrated battery capable of finely regulating the charge and discharge of energy could arrive on the market. This would bring enormous advantages in the integration of photovoltaics in the grid, removing any controversy over the dispatching costs of renewables. According to the Vanderbilt researchers at the base of the silicon supercapacitor there would be a very simple idea: instead of accumulating energy through chemical reactions as is done with batteries, this supercapacitor replenishes by accumulating ions on the surface of a porous material. As a result, it can charge and discharge in minutes, instead of hours, and can work for millions of charge / discharge cycles instead of a few thousand cycles. But if until yesterday it was possible to obtain these results only with active carbon supercapacitors, able to accumulate little energy compared to lithium-ion chemical batteries, or on relatively thick layers of graphene which is very expensive, the accumulators studied by Vanderbilt university they are based on a porous silicon layer made by electrochemically scratching a silicon wafer. This silicon surface was covered with a carbon layer to avoid some of the typical problems of silicon when it comes into contact with the chemical agents present in the supercapacitor electrodes. The carbon layer was not made by cooking the wafer at very high temperature (as is done with the graphene layers, which are obtained with a temperature of 1,400 degrees) but by making it at a more moderate temperature: 600-700 degrees. The result was to obtain a layer of graphene very few nanometers thick which manages to stabilize the silicon and make it suitable for use in supercapacitors. The prototype created consists of 5-10 layers of graphene on the silicon wafer for 2-3 total nanometers in thickness, just enough to make the silicon supercapacitor much more efficient and economical than traditional ones. “Despite the excellent performances we achieved – explains Cary Pint who coordinated the research – our goal was not to get a record. It was to develop a road map towards integrated energy storage. Silicon is an excellent material to focus on because it is the basis of most of our modern technologies. In fact, much of the silicon of existing devices remains unused because it is very expensive to produce extremely thin wafers “.

SOURCE: greenbiz.it

Recent Comments