New Supercapacitor to Help Wearable Electronics

This week, researchers have demonstrated their design for a new supercapacitor that provides a potential power solution for wearable electronics. What problems do wearable technologies face, and how does flexible electronics help to make wearable devices a reality?

Ridged Designs

The wearable electronics industry is currently in its infancy, and products in this field are often novelties at best. While smartwatches and health monitors do exist, they are barely wearable often being bulky and unsightly. If a piece of technology is to be considered truly wearable, it should be worn like clothes, and be comfortable to use. Watches can often cause discomfort to skin with their straps while arm worn phones are heavy and can cause noticeable strain. The reason that modern electronics are not suitable for wearable technologies is that they are inherently ridged. The die that holds the microelectronics is a solid piece of silicon, while the PCB that the die mounts to needs to be ridged to prevent damage to the soldered pads. Thus, in order for wearable electronics to become a reality, electronics that can flex with the body are needed that do not cause irritation, and are light enough to not be a burden.

One example of a product that can be considered to be truly wearable are the smart socks developed by a team of engineers that allow diabetic patients to log the temperature at multiple points in their feet. The sensors are woven into the material to provide a sock that, when worn, is no different to a typical sock. However, recording sensory information uses very little power, and the circuit that processes the information is still mounted in an embedded ridged container. Even if the processing circuitry was made flexible, the power source would still be ridged. Thus, not only do electronics need to be flexible, so do their power sources!

Introducing Flexible Supercapacitor

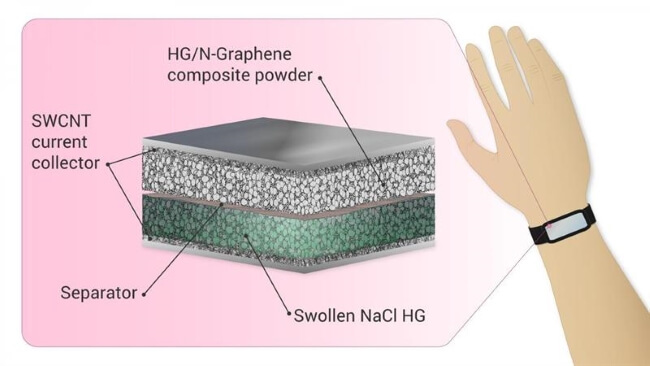

A team of researchers from Aalto University and MIT have developed a supercapacitor which provides high-performance, is cheap to manufacture, environmentally friendly, and flexible. Typical batteries require the use of organic solvents or potent acidic compounds which are both hazardous and non-environmentally friendly. The design of the supercapacitor, developed by the research team takes advantage of graphene, salt, and nitrogen, all of which are environmentally friendly compounds. The capacitor, split into two layers, has a top layer made up of graphene flakes doped with nitrogen, and then suspended in hydrogel. The bottom layer has NaCl (salt) suspended in hydrogen, and the two layers are separated by a thin insulation layer. The entire structure is then further sandwiched in a SWCNT current collector (i.e. single-walled carbon nano-tube), to create a supercapacitor that is flexible.

The benefits of such a supercapacitor are its fast charging/discharging rates, and long life-cycles, two advantages that most battery technologies suffer from. This allows for devices to be quickly charged while also having the capability to flex with the body making it an ideal power solution for wearable electronics. The environmental factor also provides the opportunity for disposable electronics with minimal environmental impacts as well as providing a non-toxic solution for power.

“We fabricated a prototype with unchanged performance under the 50% strain after a thousand stretching cycles. To ensure lower cost and better environmental performance, we used a NaCl-based electrolyte. Still the fabrication cost can be lowered down by implementation of 3D printing or other advanced fabrication techniques,”

- Skoltech Professor Albert Nasibulin

Conclusion

Supercapacitors provide large energy densities, and can be incredibly useful in low power applications. The ability to make them flexible provides designers with the ability to have flexible power storage, and having a supercapacitor that is environmentally friendly helps to create safe products. However, supercapacitors, despite their advantages, can be dangerous as a result of their high energy densities and ability to quickly discharge. Thus, for supercapacitors to be utilised in wearable electronics, safety measures will need to be considered especially when integrating potentially explosive devices into flammable materials.

FONTE: Electropages

Ultima consultazione del 10 Agosto 2020

Recent Comments